glass alchemy

a series of experiments to test the mechanical and chemical properties of glass by combining it with metals.

material study & glassblowing

fixation

the act, process, or result of fixing, fixating, or becoming fixated. in alchemy, fixation is a process by which a previously volatile substance is ‘transformed’ into a form (often solid) that is not affected by fire. it is the third step of the twelve-step process for manufacturing the philosopher’s stone.

with ‘fixation’ as a starting point the project was inspired from the manufacturing process of gorilla glass, which is dipped in a hot bath of molten potassium salt to strengthen it.

the test samples

five test samples were created, two of which were treated with copper at different temperatures, two others were treated with steel and the last one was clear glass used as the control. since glass brings out the true colour of metal salts through ion exchange, all the colours are a by product of the glass blowing process used to manufacture the test samples.

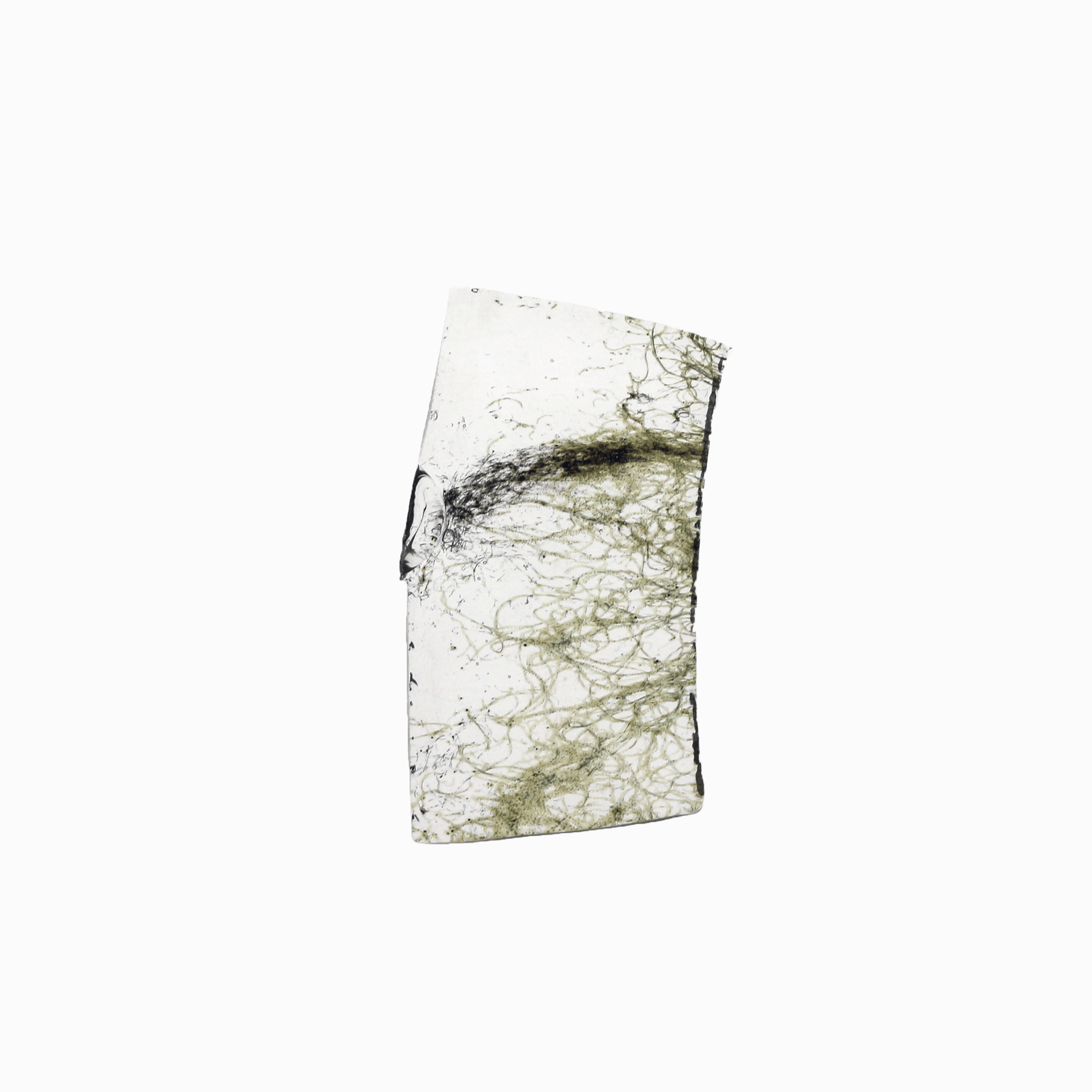

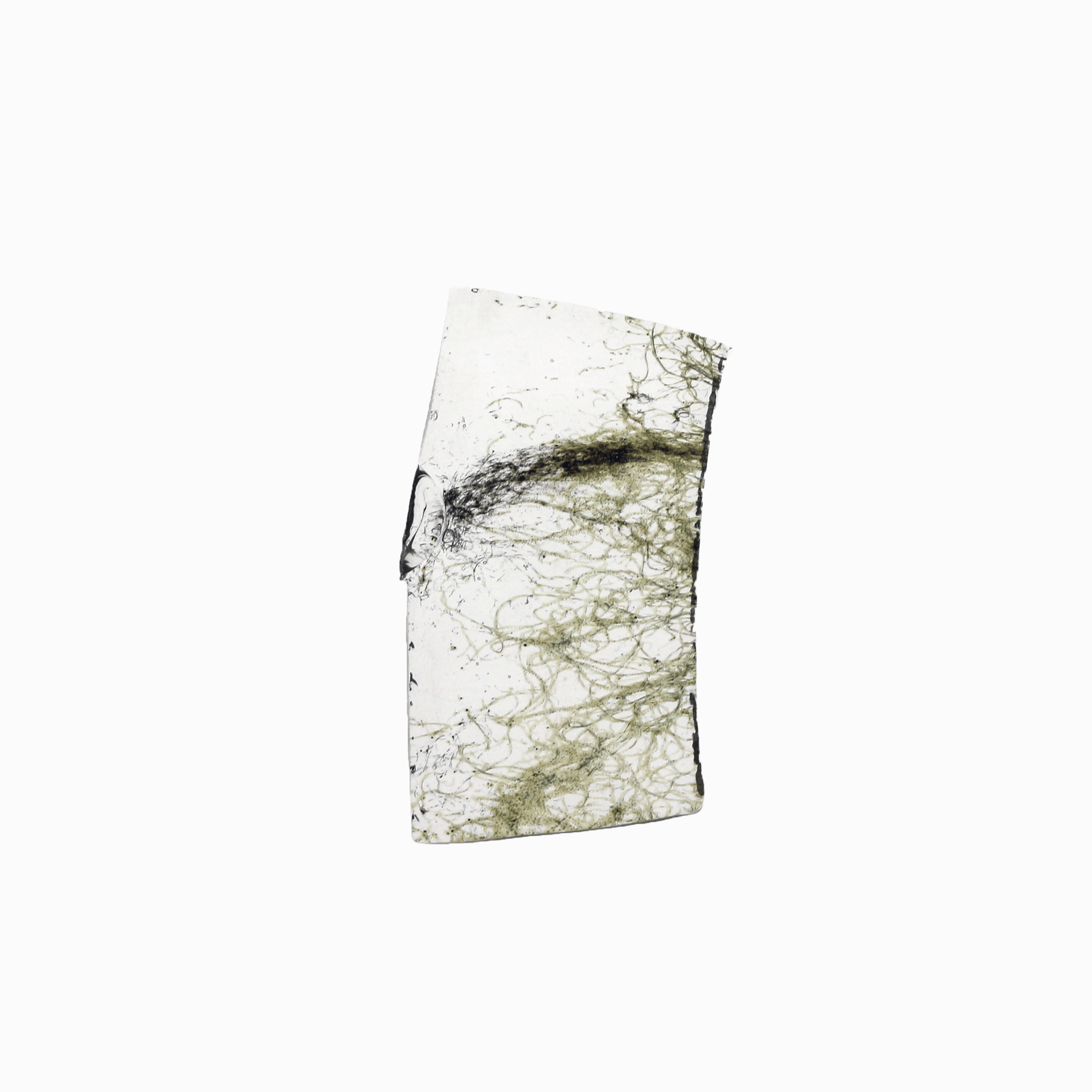

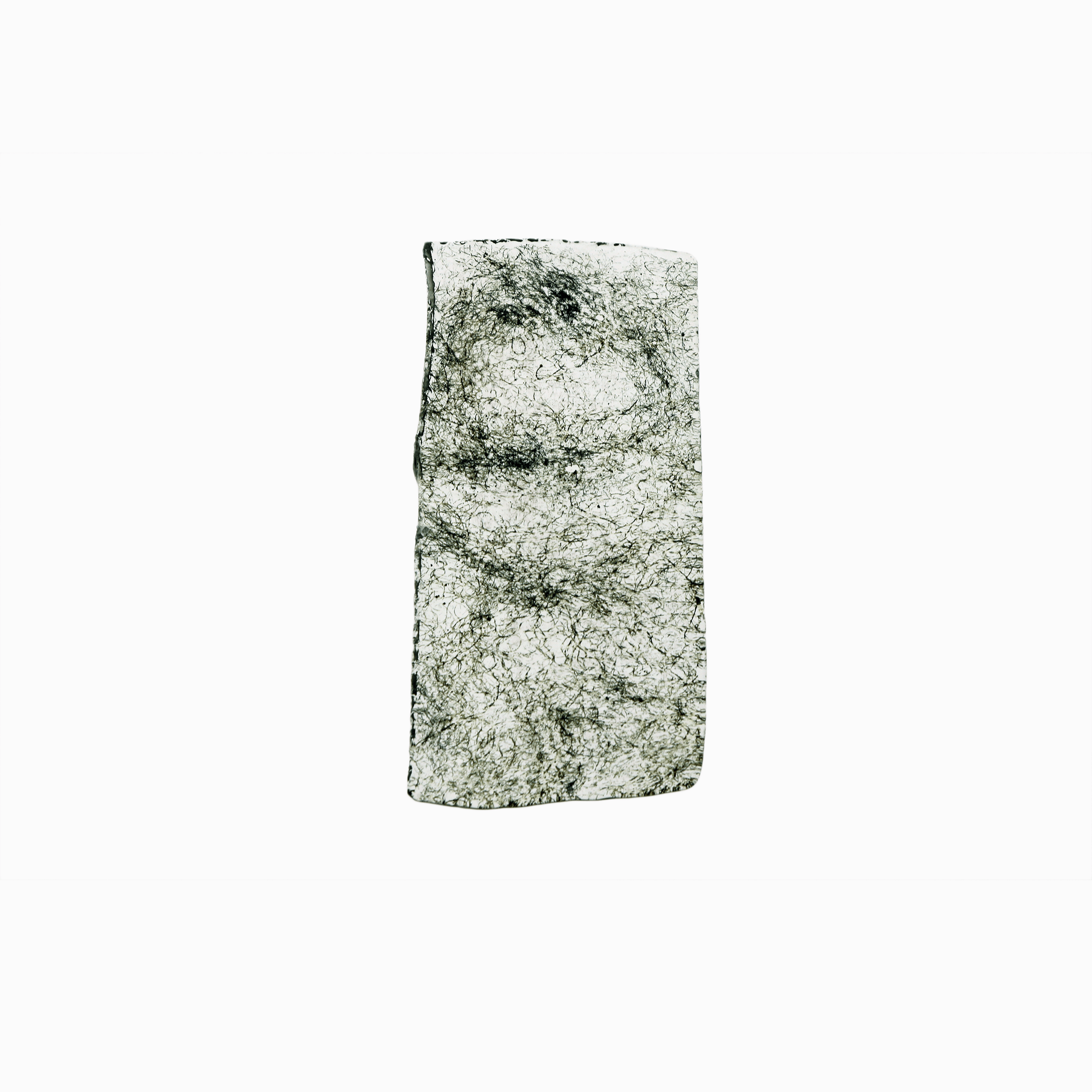

steel sandwiched between glass

glass with copper heated to blue oxide

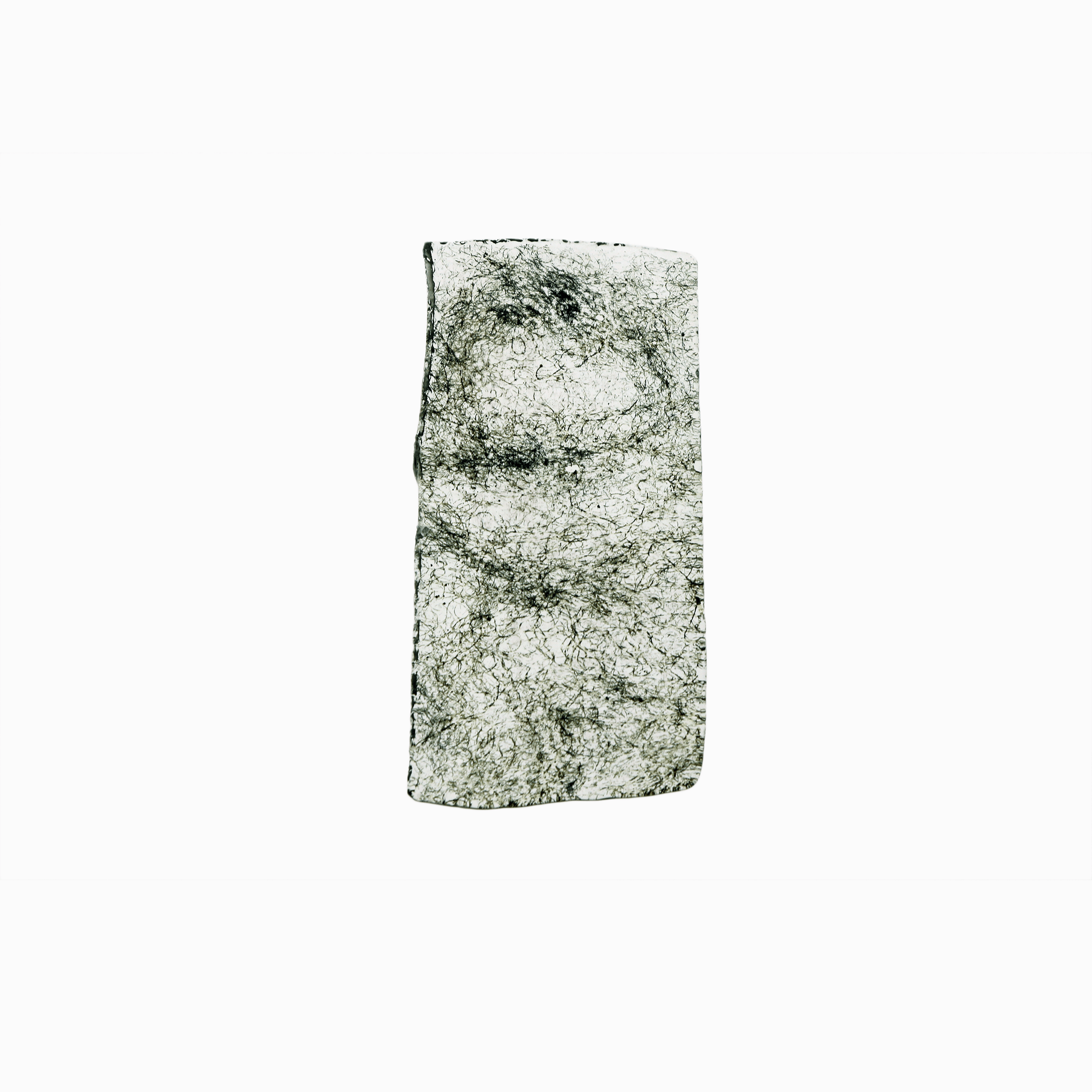

glass with steel on surface

glass with copper heated to red oxide

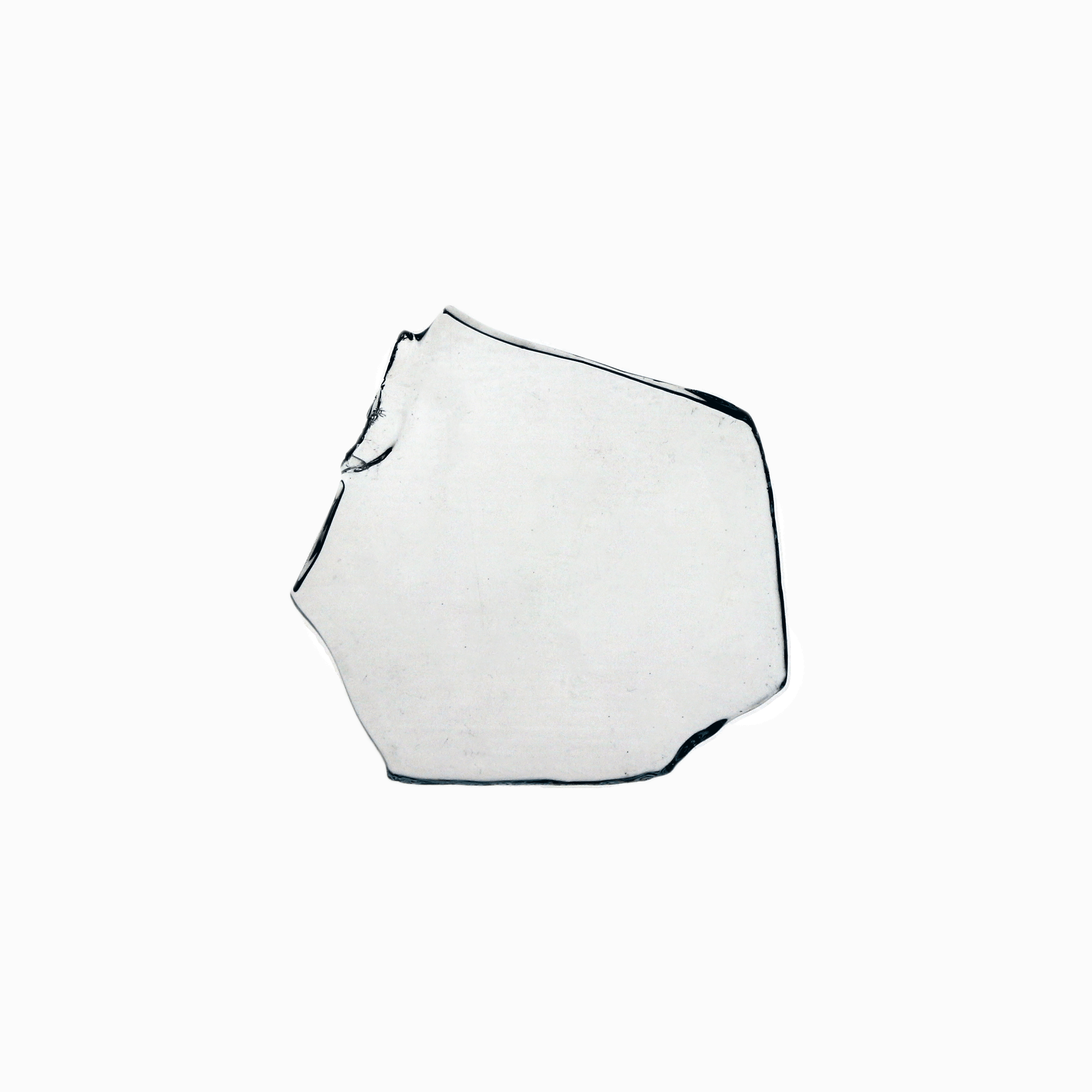

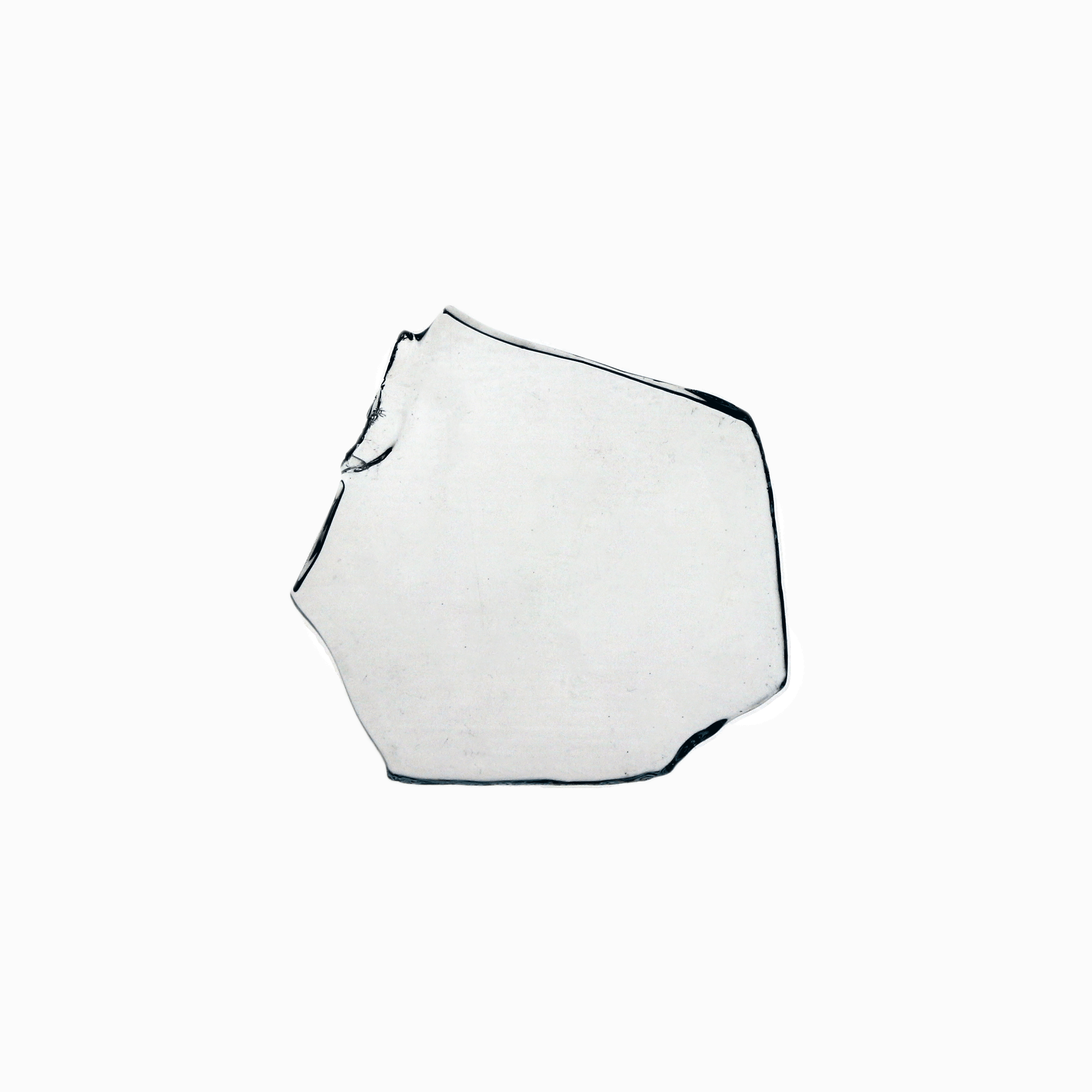

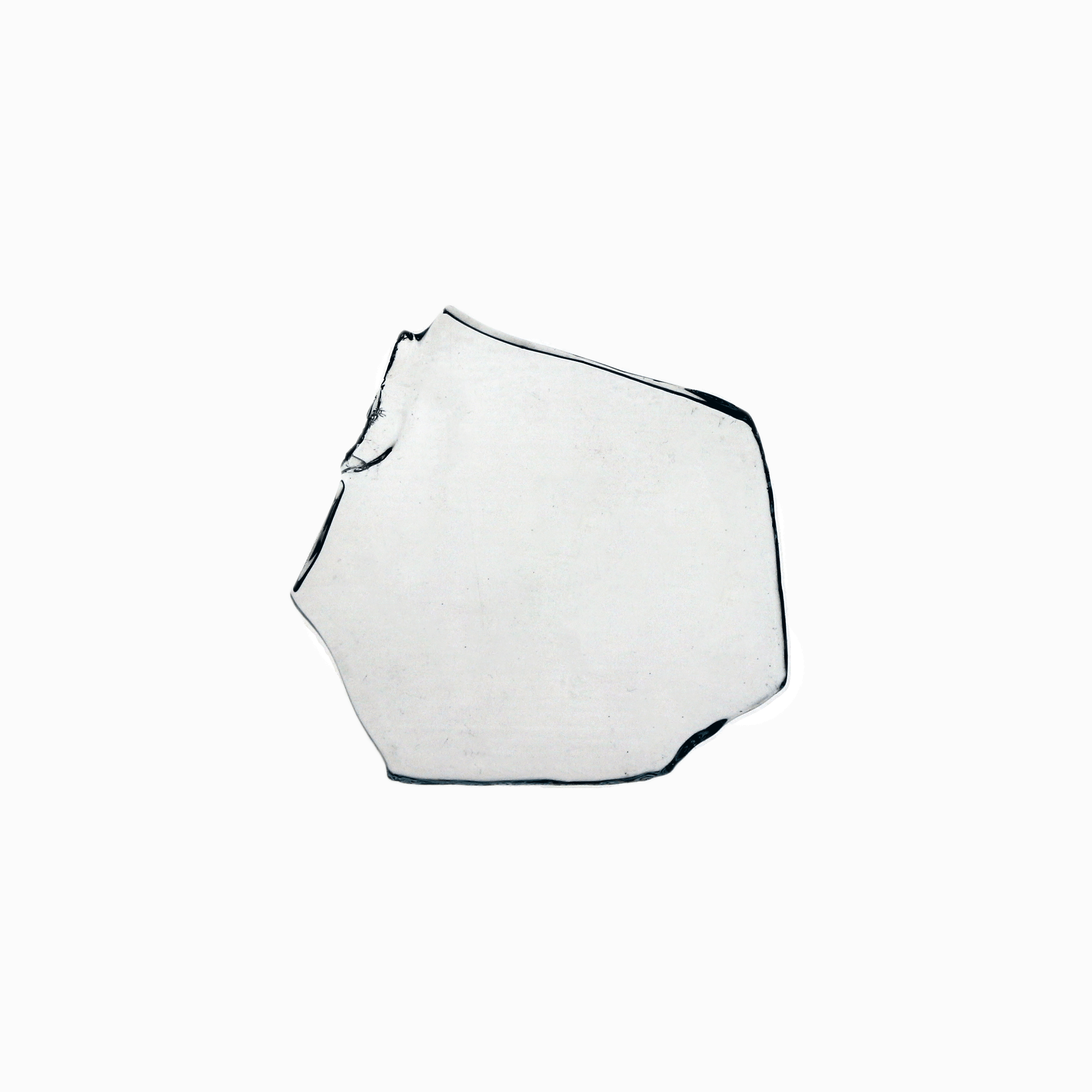

clear glass as the control

the experiments

a series of experiments to test the mechanical and chemical properties — hardness, tensile strength, impact and bendability.

01/ hardness

moh’s hardness test

conducting the moh’s hardness test on the glass samples, which involves attempting to make scratches with objects with incrementing hardness. the objects in ascending order — fingernail, copper penny, knife, steel nail and drill bit.

scale:

> 8.5

6.5 - 8.5

6.5 - 8.5

6.5 - 8.5

6.5 - 8.5

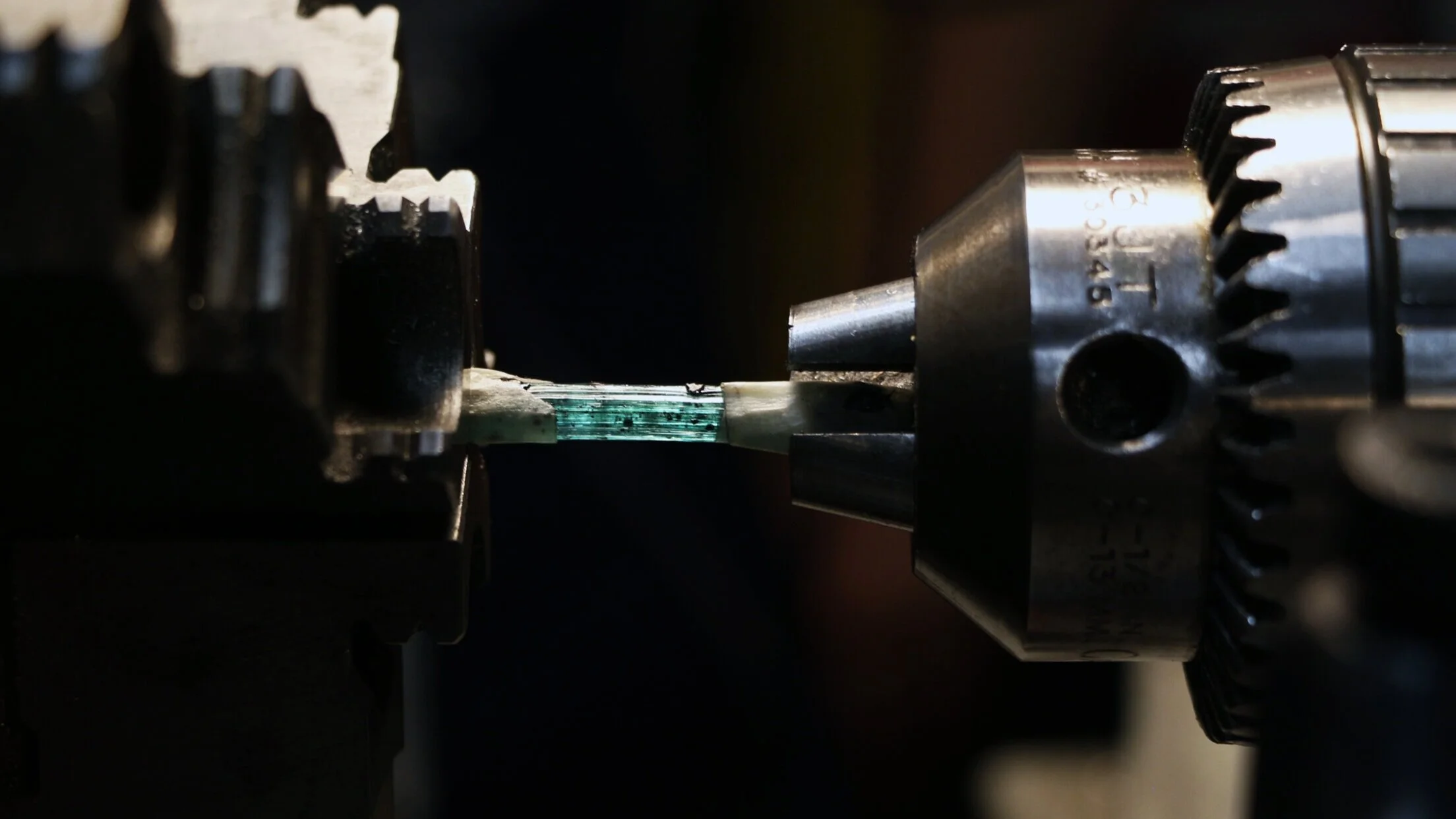

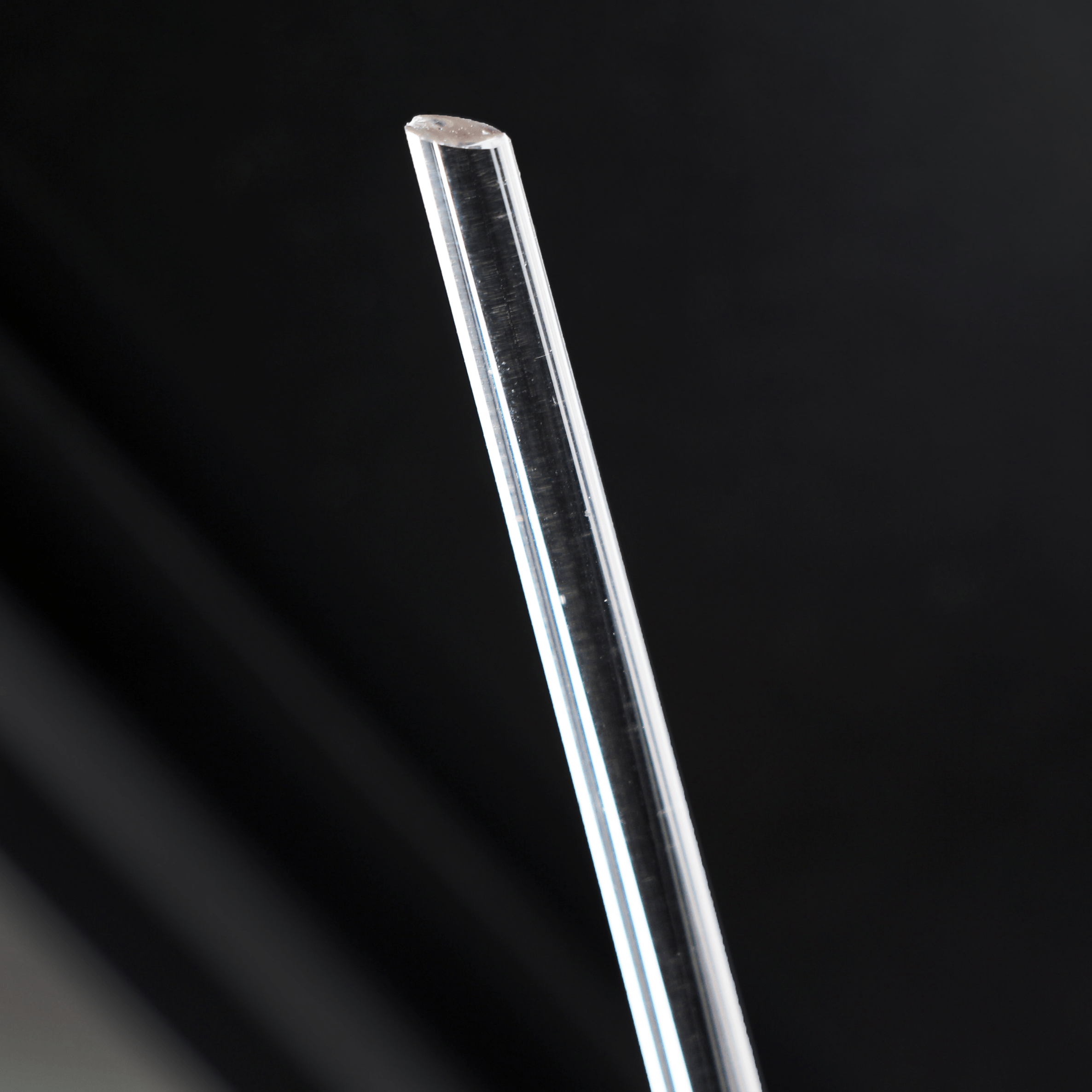

02/ tensile

a lathe used to measure the tensile strength of a copper glass dowel.

the absence of measurement tools, forced me to get creative in rigging different machines to pull off the same task. since the standard deviation would be the same across all samples, it becomes an accurate exercise to gauge which sample did better.

scale: (inch scale)

1/4th of an inch till it snapped

1/16th of an inch till it snapped

0-1/16th of an inch till it snapped

03/ impact

impact test from ankle, knee and waist height.

inspired by how england’s king henry i used his ‘foot’ as the new standard unit of length — i used my ankle, knee and waist as the standard for the impact test with the different samples.

scale:

chest > waist > knee > ankle

shattered at waist height

shattered at waist height

shattered at knee height

shattered at knee height

shattered at knee height

04/ bendability

drill press chuck used to test for pliability.

even though the accuracy of this test had a larger standard deviation than the others, the scale gave accurate enough data to compare the samples.

scale: (inch scale)

1/4"

1/8th"

1/8th"

1/16th"

1/16th"

/ the results

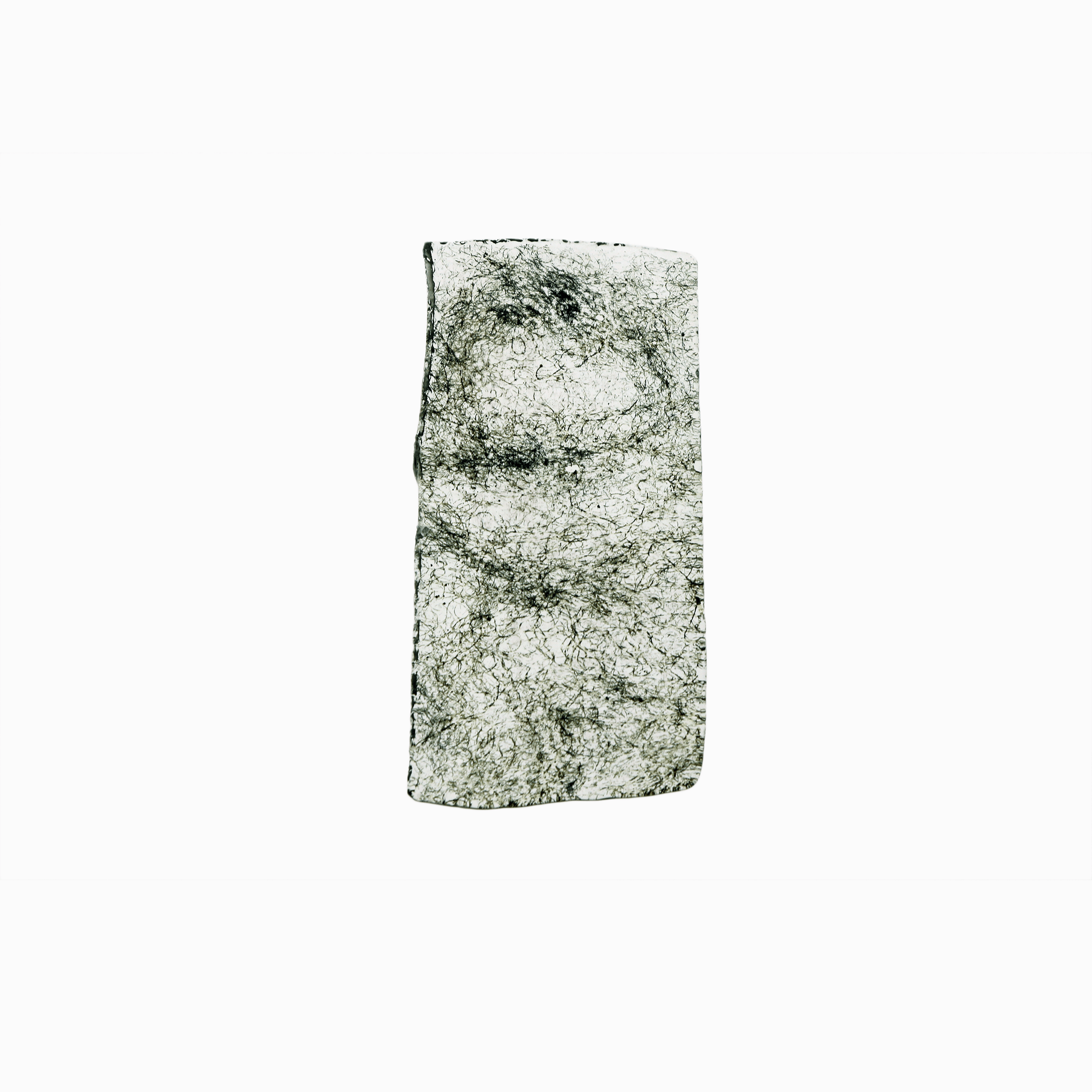

steel on the surface of clear glass

in general it is safe to conclude for the most part, the clear glass was the most structurally stable, which makes sense.

the copper glass performed better than the steel in the bendability tests.

the really astonishing results however were shown by the two steel samples. they were quite hard, especially the sample with the steel layered on the surface (left). this particular sample did quite well on the mohr’s hardness test, developing hardly any scratches. however it remains brittle as seen in the impact and bendability tests.

this result coincides with the practical use of silica in the steel manufacturing process, where it is used to remove excess oxygen making the steel harder.

authors note: this project was taken beyond experimentation and into exploration where copper and glass were used to explore their capabilities in electrical conductivity in the project ‘dirty ice’.